Car wash plant by Jürgen Keil

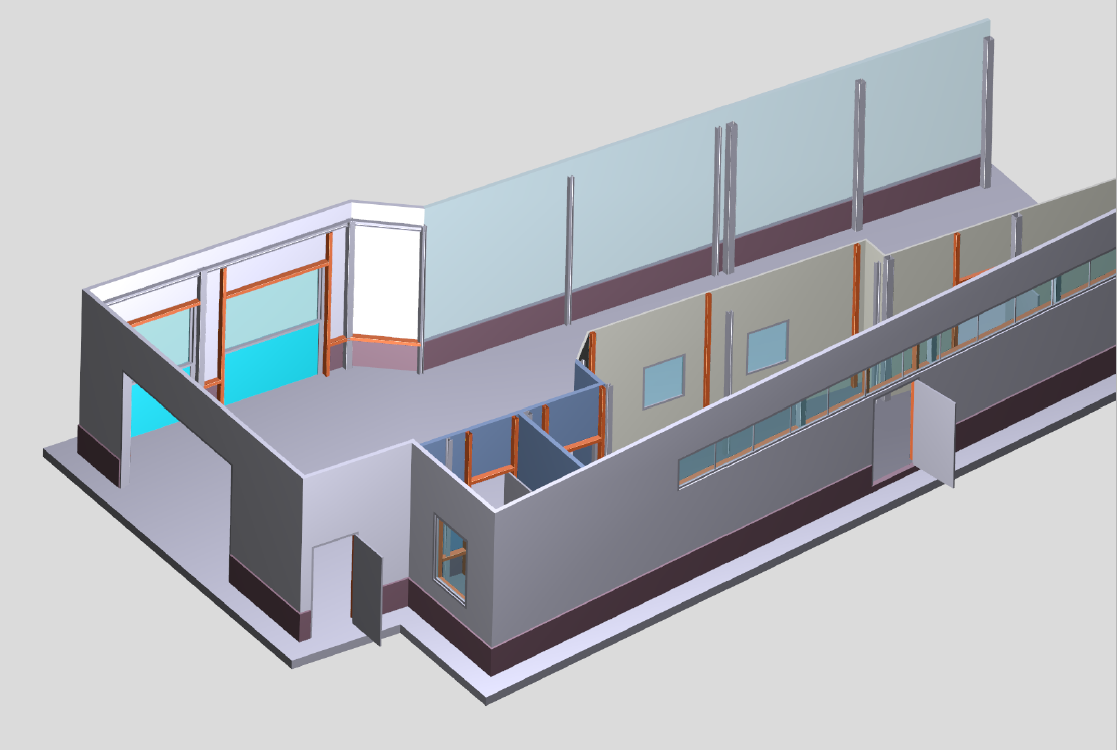

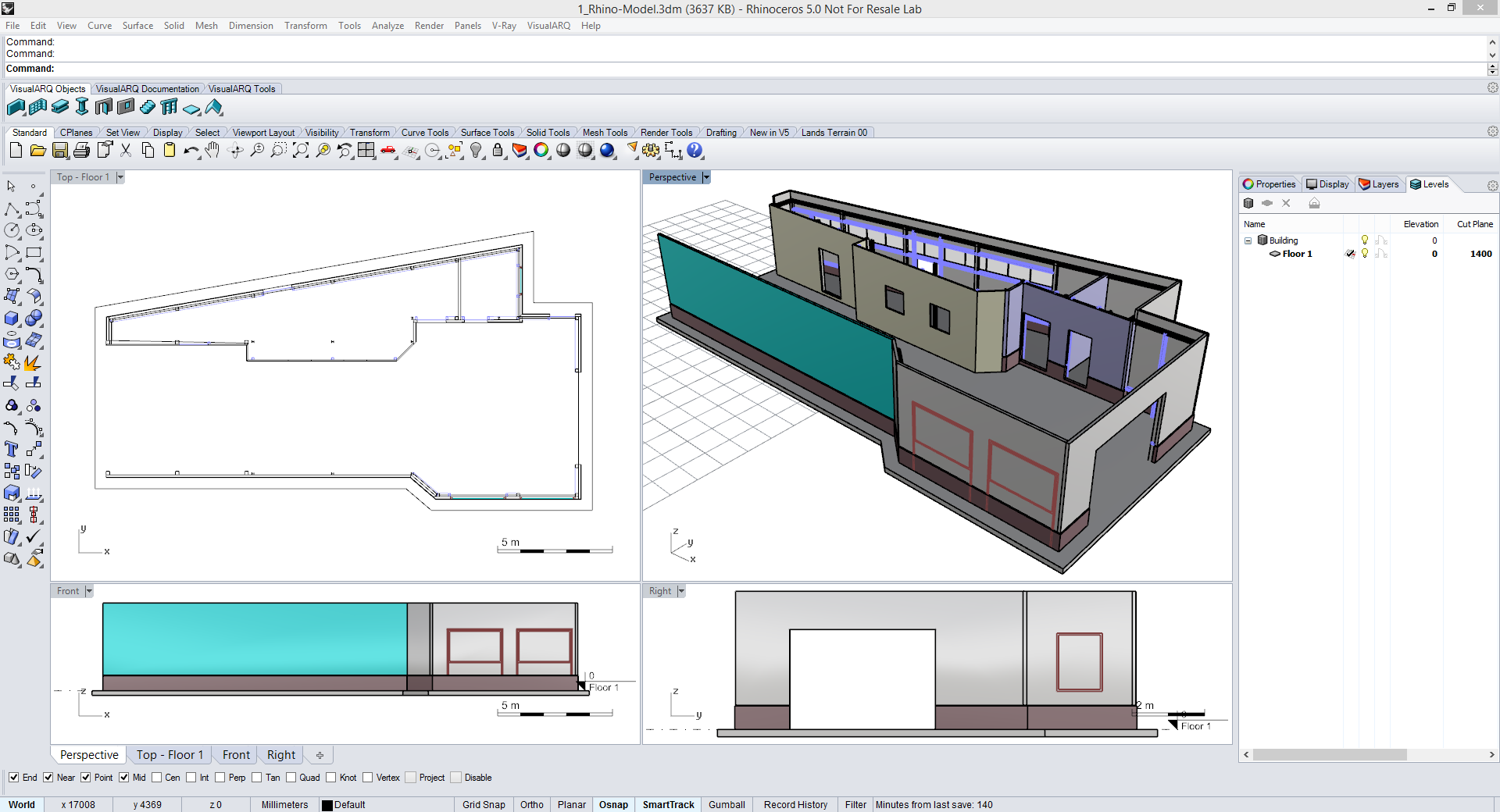

This project features a car wash plant of nearly 200 sq meters by engineer Jürgen Keil. VisualARQ was used to generate the 3D model and then to export it to IFC, in order to produce the final shop drawings.

Jürgen Keil explains his project workflow with Rhino and VisualARQ:

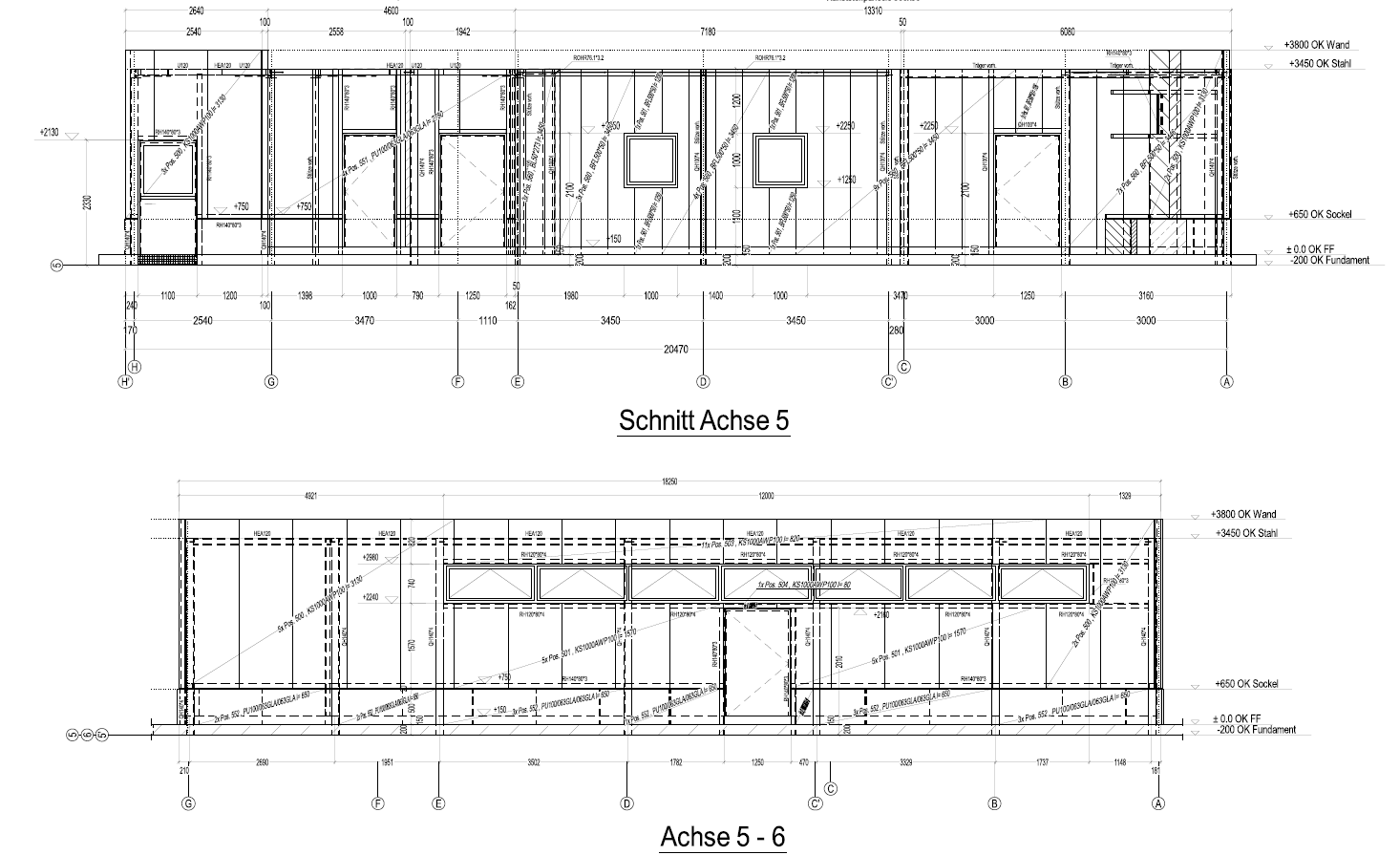

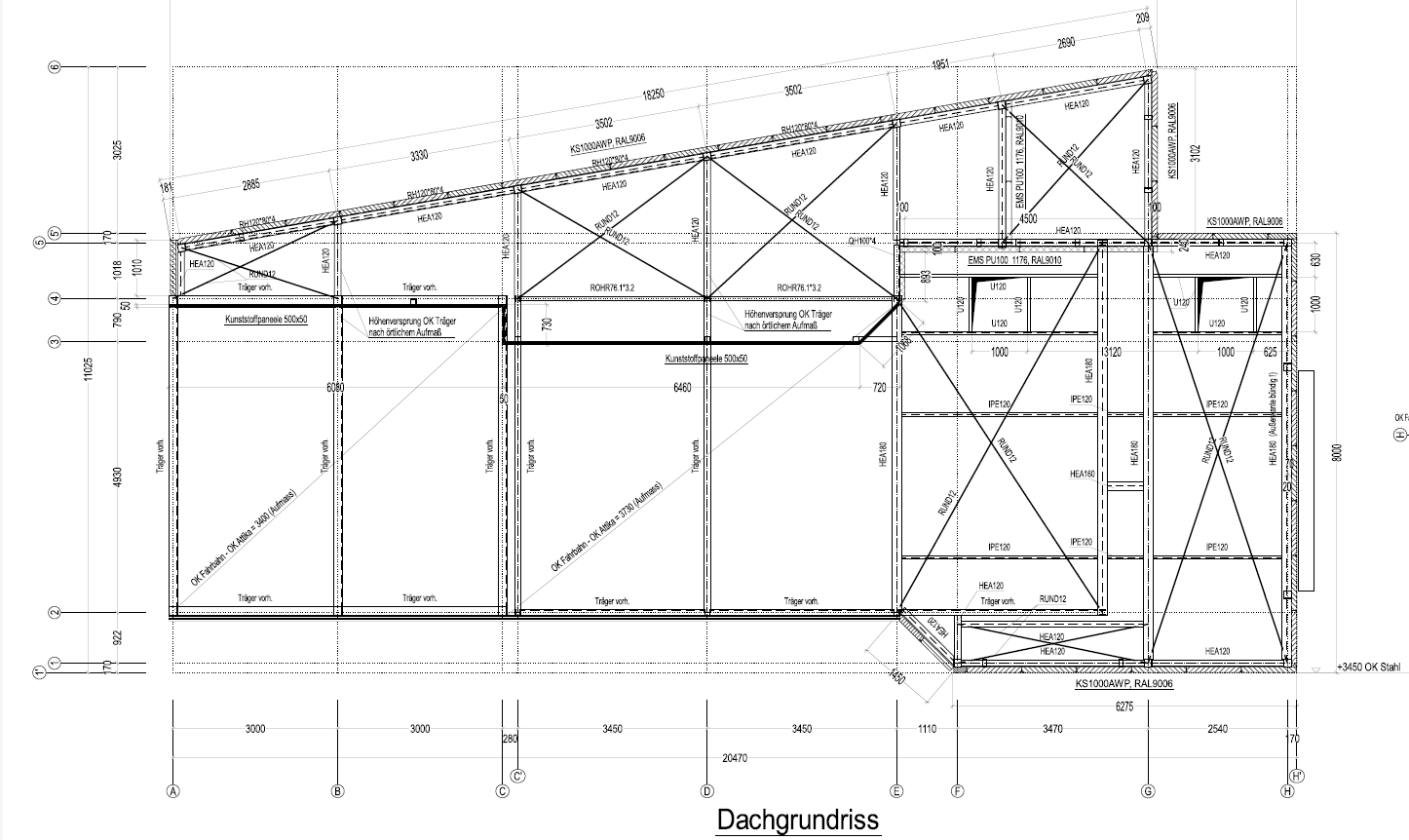

He first got the project drawings (plans, sections and elevations) from the architect in .dwg format. He had to assemble the drawings in 3D in order to use them as a reference to create the 3D model.

According to Jürgen Keil, the biggest advantage that VisualARQ provided to the project was “the very fast generation of a rough 3D model, which led to a better communication among the relevant parties (architect, engineer and customer).”

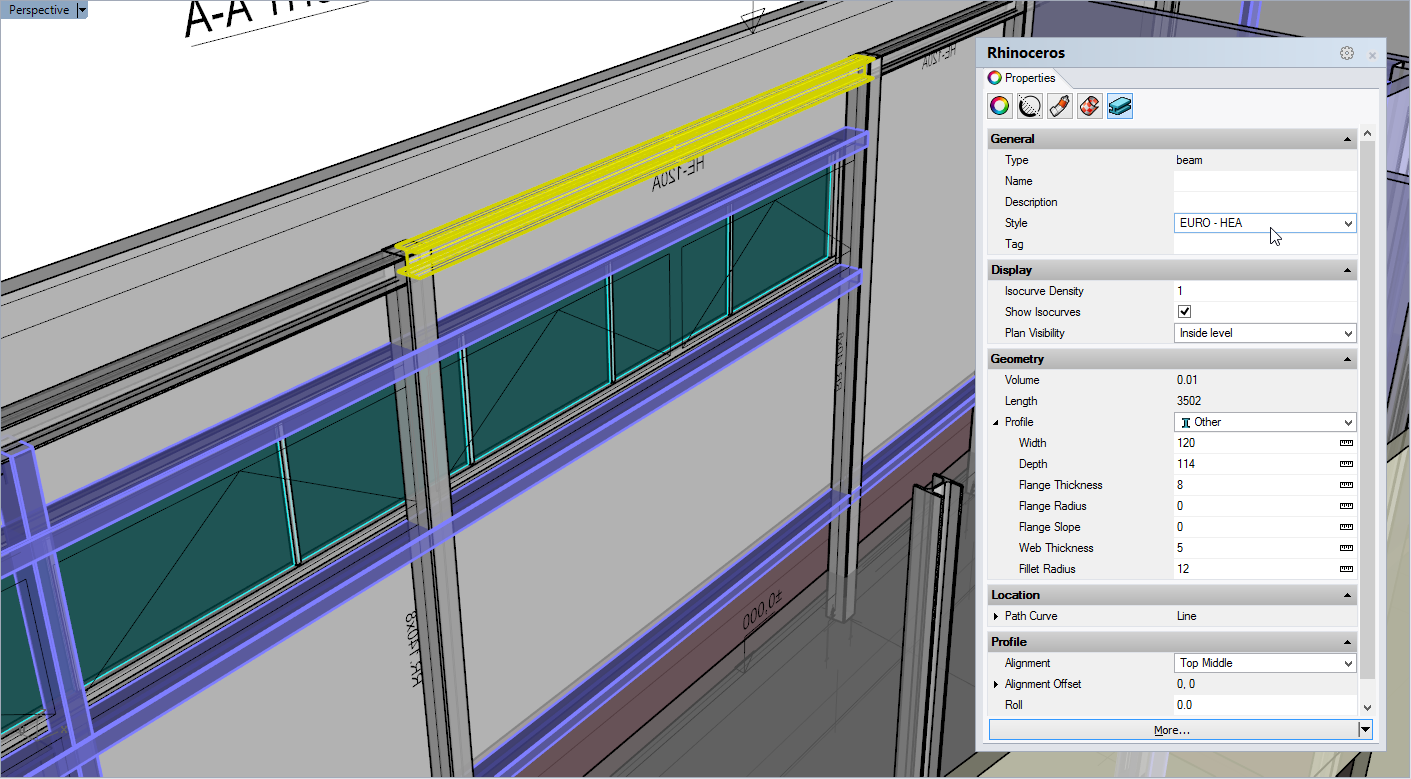

Secondly, with VisualARQ parametric approach, he was able to develop his own solutions and modify the model in few clics. That was particularly useful for the different beams and columns whose cross section steel profiles needed to be changed constantly, as well as for the wall thicknesses.

This easy and fast way to modify the geometry sped up the project development dramatically and helped in making decisions faster.

Finally, with the help of VisualARQ, he exported the model to IFC and imported it to Revit and BOCAD to finish the final shop drawings. Once the model was exported, VisualARQ objects were used as a first draft for the final shop drawings and construction details. VisualARQ walls were used as references to create individual wall parts in BOCAD, and VisualARQ doors and windows were revised and replaced by more detailed ones.

Dipl. Ing. Jürgen Keil

Martin-Luther-Str. 53a

D-46284 Dorsten

E-mail: keil@keil-systemtechnik.de

Website: www.keil-systemtechnik.de

Client:

S+O Projektgesellschaft mbH

Firmensitz: Feldmarkstr.2, 46282 Dorsten, Deutschland

Geschäftsführer: Dipl.-Ing.Volker Knigge

Handelsregister Gelsenkirchen HRB 6506

USt.-Id.-Nr.:DE813122152